High Precision for the Graphic Industry

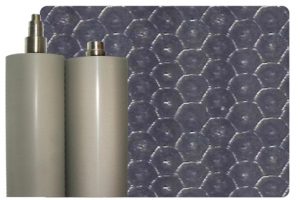

Cylinders for tint sleeve

The IBESLAB inking cylinders are designed to easily exchange the outer rubber sleeve that applies the varnish or ink to the substrate.

This system allows for the application of continuous varnish or color backgrounds without visual lines. It allows the printer to adjust the varnish contribution at the precise band width on the press, easily changing the measurement and rubber hardness.

Technical features

High Performance Materials

Made from high-quality steel, our ink rollers have a high level of precision to ensure excellent transfer of ink, varnish, or coating at any printing speed. These cylinders have ducts inside them through which compressed air is applied to facilitate the change of the inking sleeve. A desktop stand with pneumatic connection assist the change by fixing the sleeve to the cylinder assist the change by fixing the sleeve to the cylinder

Compatibility with Various Printing Systems

Our cylinders are installed in flexible groups and they are compatible with other industrial online printing systems, in addition to flexography, such as offset, typography, or digital printing, allowing for effects and finishes in various production processes.

High-Precision Surface

Thanks to advanced grinding and dynamic balancing processes, we ensure a uniform distribution of ink without irregularities, optimizing print quality and reducing material waste.

Custom Coating Options

We have a wide range of rubber and elastomer varnish sleeves with different hardnesses, designed to adapt to different types of inks, varnishes, and specific applications.

Key Benefits

🔺Uniform Ink Distribution

The design and materials of our ink rollers ensure a homogeneous transfer, avoiding overloads, irregularities, and unwanted effects in printing.

🔺Waste Reduction

Accurate ink application minimizes excessive consumption and reduces waste, optimizing costs and improving the sustainability of the process.

🔺Greater Durability and Strength

Made with high-quality materials and specialized coatings, they offer excellent resistance to wear, chemicals, and demanding conditions.

🔺Easy Maintenance and Cleaning

Designed for easy cleaning, our cylinders allow for quick removal of ink and varnish residue, reducing production downtime.

🔺Compatibility with Various Systems and Inks

Functional with a wide variety of inks (UV, solvent, water-based) and flexographic, offset, and other industrial printing equipment.

🔺Operational Stability and Constant Accuracy

Thanks to their manufacturing with minimal tolerances, the cylinders maintain consistent and unwavering performance over time, guaranteeing high-quality results in every print.

Industrial Applications

Printing varnish

Essential in finishing processes, they allow for a uniform application of protective varnishes for ink or visual effects on to achieve striking visual effects..

Flexographic Printing

The inking cylinders ensure precise and uniform ink transfer, avoiding the typical line of union when printing with a cliché, on labels, paper, or plastic film, optimizing quality and reducing waste.

Applying Adhesives or Lamination

Used in the label printing and conversion industry, these cylinders ensure controlled distribution of adhesives, improving the bonding of substrates and optimizing material consumption.

Personalized Advice

Our technical sales department offers consulting services to select the appropriate cylinder and rubber sleeve based on the customer’s specific needs.