Home » Flexography » End seals

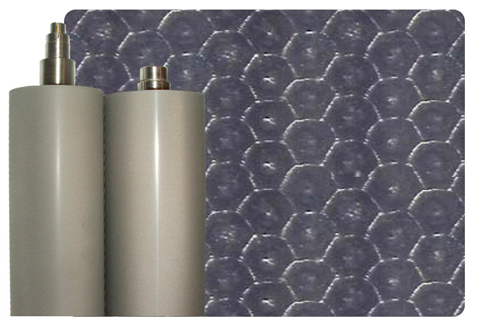

The Ibeslab end seals, for flexo ink ducts with closed chamber systems, offers a guaranteed seal against ink leakage. This element plays an important role in the printing unit together with the doctor blade and the anilox cylinder.

In continuous contact with the doctor blade, anilox and inks, it is subjected to constant stress and must maintain its dimensional stability for as long as possible.

We manufacture the blanket to customer requirements, observing the precise dimensions of the different machines such as: Comexi, Windmoller (W&H), Giave, Schiavi, Bobst (Rotomec, Fischer, F&K), Omet, Nilpeter, Sicosa, Uteco, Gallus, Carint as well as the manufacturers of closed chamber systems such as Tresu, Harris&Bruno, Akeboose, Printco, etc.

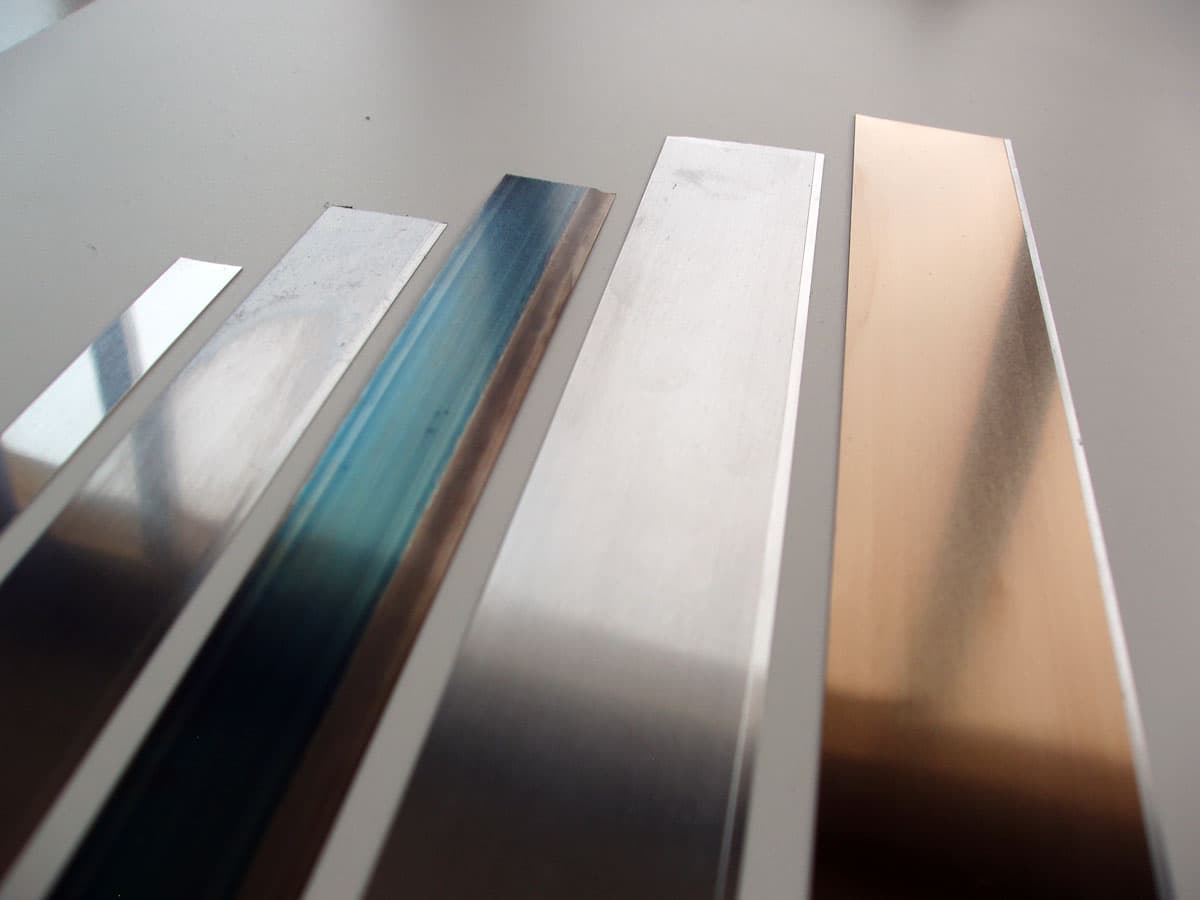

Our manufacturing process, using different high precision cutting systems, depending on the design and the tolerances determined, avoids curvatures in the edges of the plug and ensures dimensional stability at the lowest cost.

We manufacture seals compatible with all flexographic machines by selecting the appropriate material to manufacture it, meeting the requirements of hardness, chemical resistance, rigidity, mechanical strength and flexibility. These criteria allow us to obtain a high performance end seal, with greater resistance to wear due to friction with the anilox, which increases its useful life.

The printing quality of the flexo press as well as its productivity can be improved by choosing an Ibeslab side seal.

It depends on the type of machine, the design of the closed chamber and the type of inks used. We have more than 10 different materials to cover all needs.

We manufacture different models that can withstand more than 500,000 metres of printing. Many printers demand that the end seal and the doctor balde has a high resistance and make the print very productive.

Undoubtedly, the end seals function in flexo goes beyond ink retention. It is the cushioning of the pressure of the anchor against the anilox. Its geometry and flexibility is the key to good and stable ink transfer.

Yes, that is our speciality, to manufacture side seals for closed chambers with the optimum shape, material and density for our customer.

Contact Us

If you want us to contact you or have any questions we will be happy to assist you.

Ibes Gestión y Desarrollo, S.L.

Cádiz, 20 – Pol. Ind. L’Alfaç II

03440 IBI – Alicante (España)