- Home

- Products

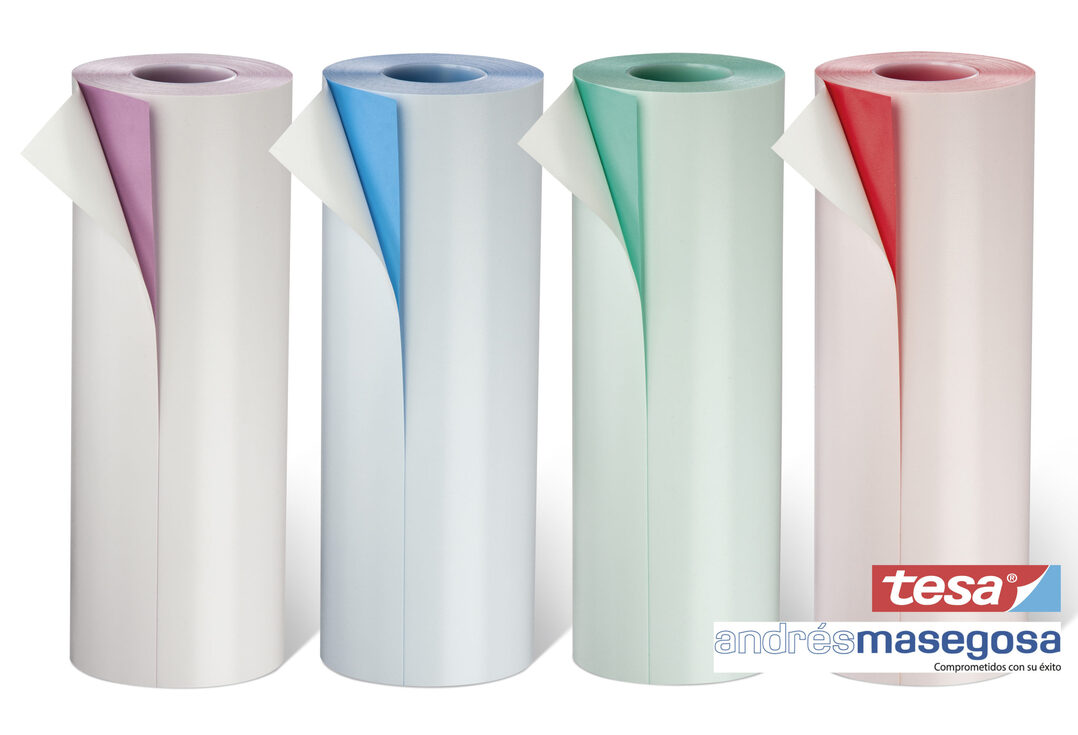

- Plate mounting tape

- Doctor Blade for Flexography

- Graphic Arts Ink Cleaners

- Tint sleeve

- Anilox cylinder

- Anilox cleaning products

- Printing, magnetic and rubberised cylinders

- Seaming solvent – Shrink sleeve

- Band cleaner

- End seals

- Screen printing squeegee

- Transfer paper

- Hot Melt Adhesives

- Automatic cleaning equipment for flexo printing

- Screen printing cleaning equipment

- Silk-screen printing machine

- Printing techniques

- News

- Our Team

- Contact

- Home

- Products

- Plate mounting tape

- Doctor Blade for Flexography

- Graphic Arts Ink Cleaners

- Tint sleeve

- Anilox cylinder

- Anilox cleaning products

- Printing, magnetic and rubberised cylinders

- Seaming solvent – Shrink sleeve

- Band cleaner

- End seals

- Screen printing squeegee

- Transfer paper

- Hot Melt Adhesives

- Automatic cleaning equipment for flexo printing

- Screen printing cleaning equipment

- Silk-screen printing machine

- Printing techniques

- News

- Our Team

- Contact

- Home

- Products

- Plate mounting tape

- Doctor Blade for Flexography

- Graphic Arts Ink Cleaners

- Tint sleeve

- Anilox cylinder

- Anilox cleaning products

- Printing, magnetic and rubberised cylinders

- Seaming solvent – Shrink sleeve

- Band cleaner

- End seals

- Screen printing squeegee

- Transfer paper

- Hot Melt Adhesives

- Automatic cleaning equipment for flexo printing

- Screen printing cleaning equipment

- Silk-screen printing machine

- Printing techniques

- News

- Our Team

- Contact

- Home

- Products

- Plate mounting tape

- Doctor Blade for Flexography

- Graphic Arts Ink Cleaners

- Tint sleeve

- Anilox cylinder

- Anilox cleaning products

- Printing, magnetic and rubberised cylinders

- Seaming solvent – Shrink sleeve

- Band cleaner

- End seals

- Screen printing squeegee

- Transfer paper

- Hot Melt Adhesives

- Automatic cleaning equipment for flexo printing

- Screen printing cleaning equipment

- Silk-screen printing machine

- Printing techniques

- News

- Our Team

- Contact