Home » Flexography » Plate mounting tape

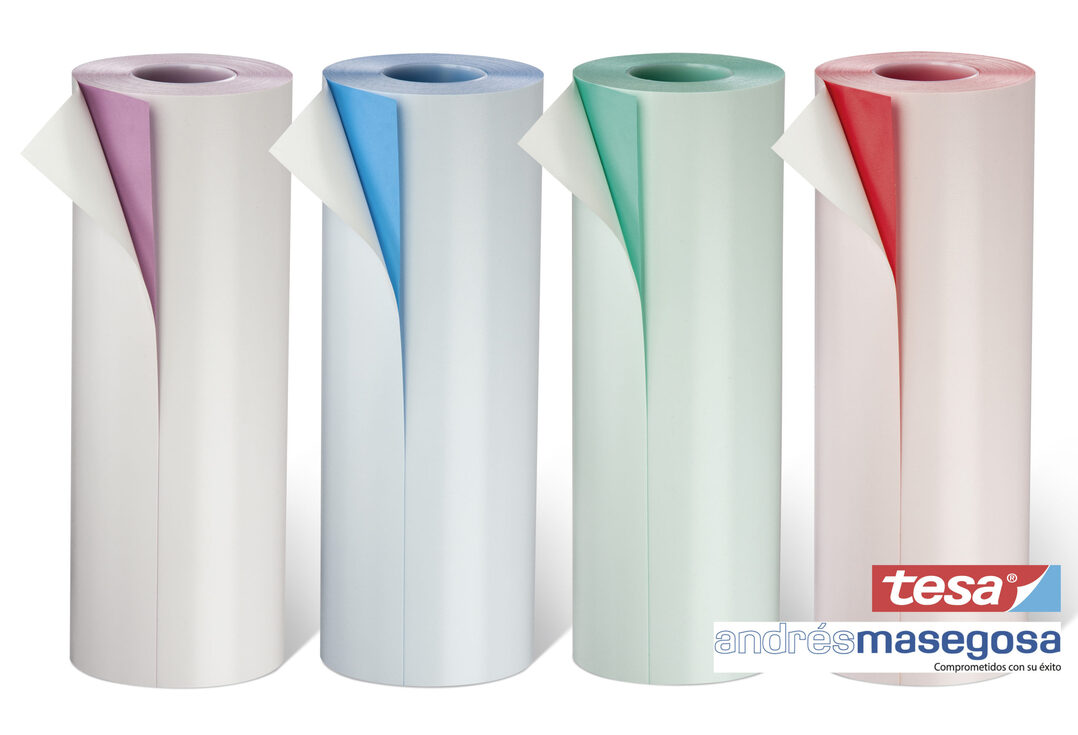

The use of foams of different densities allows the printer to achieve better flexo print quality. To achieve optimum screen definition while minimising loss of detail, it is key to choose low density foams, also known as soft or extra soft. This hardness reduces the dot gain of the plate and helps to control machine vibrations.

If we are looking for a higher ink saturation or a uniform ink background, without defects such as water or pinholing, it is advisable to opt for TESA Softprint double-sided adhesive tape with high density, i.e. a hard tape. This choice will help to increase the ink volume and achieve a more even distribution on the substrate.

However, more and more printers are looking for an intermediate density, such as the purple softprint, which allows them to print both backgrounds and screens with high quality and with remarkable results in terms of quality. Thanks to the versatility of this hardness it allows them to reuse it making their printing process more cost effective and sustainable.

Although there are other variables, such as squeegees or aniloxes, that can affect the printing process, in today’s flexographic industry double-sided adhesive tapes play an important role that goes beyond the fixing of the photopolymer plate.

The different density of the foam allows us to obtain a good definition in the screens with a minimum dot gain if we choose low density foams, also called soft or extra soft. If we are looking for a high ink supply or homogeneous ink backgrounds, without water or pinholing, the choice of a TESA Softprint double-sided adhesive tape of high density, or hard, will help us to increase the volume of ink and its better distribution. But more and more printers are looking for an intermediate density, which allows them to print good quality backgrounds and screens, with versatility and remarkable levels of quality.

TESA Softprint adhesive tapes have a polyester core which gives them stability and resistance to the stresses that can occur during the application process. The internal foam composition is formulated to withstand long print runs and even the re-use of the foam for different clichés. This special formulation acts as a shock absorber that compresses and recovers quickly ensuring accurate ink transfer to the substrate.

TESA SoftPrint tape offers cost savings and increased productivity in the printing process. Its adhesive allows the cliché to be easily repositioned and removed without leaving residue, making it easy to reuse for different jobs. In addition, the foam technology ensures stable quality with high resistance to degradation. This allows for a significant reduction in consumption.

Highlights:

| x-Soft | Soft | Medium | Medium Hard | Hard | Range 0.38 thickness | |

| Referencia de Producto | ||||||

| tesa Softprint® STM | tesa® 52018 | tesa® 52017 | tesa® 52016 | tesa® 52015 | tesa® 52014 | The mounting of clichés takes place in conditions that are neither very clean nor very warm, thanks to its high tack adhesive. This provides a high resistance to lifting of the cliché tips, thanks to its level of adhesion. |

| tesa Softprint® STM-TP | tesa® 52118 | tesa® 52117 | tesa® 52116 | tesa® 52115 | tesa® 52114 | Secure cliché mounting is essential in most cases, and this is achieved by the initial tack. In addition, a high resistance to lifting of the cliché tips is ensured by secure clamping. |

| tesa Softprint® SEC | tesa® 52818 | tesa® 52817 | tesa® 52816 | tesa® 52815 | tesa® 52814 | Quick and easy cliché mounting is made possible by the low initial tack, which allows easy repositioning under clean conditions. In addition, a secure cliché fixation without tip lifting is ensured, even in small developments, thanks to the use of a special adhesive. |

| Flex Product Design | ||||||

| tesa Softprint® FE | tesa® 53418 | tesa® 53417 | tesa® 53416 | tesa® 53415 | tesa® 53414 | This type of tape is specifically designed for cylinder or sleeve surfaces that require high standards. It allows easy and fast mounting of clichés, with the possibility of easy repositioning thanks to its low initial tack, always under clean conditions. In addition, it guarantees secure cliché fixation without tip lifting, even in small developments, thanks to the use of a special adhesive. |

Yes, there is a TESA sofprint in purple, with an intermediate hardness that allows 70 to 90% of the jobs to be carried out with good quality on a flexo printer. In the case of very large backgrounds or high-definition four-colour prints, it would be necessary to evaluate whether the quality is acceptable under the customer’s requirements.

Yes, TESA’s foam designs allow for the removal of the foam deformation plate and for the foam to maintain its performance so that it can be reused several times. This is a trend among more and more printers that improves productivity and lowers costs.

There are several solutions, such as using Tesa’s Softprint FLEX foam, or another reference that has better adhesion face to plate, applying an edge sealing tape or using the Magic CT marker when a sealing tape cannot be applied.

Yes, it is advisable to clean it so that there is no residue from inks, adhesive or the cleaners used in the process, as this can create gluing interference and lead to the cliché coming off or making it very difficult to remove the cliché at the end of the job.

Contact Us

If you want us to contact you or have any questions we will be happy to assist you.

Ibes Gestión y Desarrollo, S.L.

Cádiz, 20 – Pol. Ind. L’Alfaç II

03440 IBI – Alicante (España)