Home » Printing techniques » Rotogravure printing system. Everything you need to know

Rotogravure printing system. Everything you need to know

What is gravure printing and how does it work?

Gravure printing is a highly effective printing technique that is particularly suitable for long runs in flexible packaging. Its direct transfer approach of transferring the design from the cylinder to the substrate allows for exceptional print quality, even at very high production speeds. This makes it the preferred choice for high-volume printing of flexible packaging, ensuring high productivity and sharp, detailed design reproduction on every print.

How does the gravure printing process work?

The gravure printing process consists of several stages, including the preparation of the printing cylinder, the ink setting of the ink, the transfer of the ink to the substrate and the drying of the ink. Below is a detailed description of each stage of the process:

- Preparation of the printing cylinder: The printing cylinder used in gravure printing is made of steel or copper and is engraved with a series of cells or holes representing the areas of the image to be printed. These cells are created by chemical or mechanical processes, and their shape and size determine the amount of ink that will be transferred to the substrate during printing.

- Ink setting: At this stage, once the ink has been set to the correct viscosity, it impregnates the bas-relief engraved cylinder. Excess ink is removed from the cylinder by using a steel key with a bevelled profile or lamella.

- Transfer of the ink to the substrate: During printing, the printing cylinder is brought into contact with the substrate, be it paper, cardboard, plastic or other material, and the ink is transferred from the cells of the cylinder to the substrate by the pressure of the rubber roller. The ink flows by capillary action from the cells to the substrate contact areas, creating the final image with high quality and fine detail.

- Drying the ink: Once the ink has been transferred to the substrate, it needs to be dried before continuing to the next step of the process. This can be done by applying heat, combined with an air flow, so that the evaporation of solvents or water is accelerated, depending on the type of ink used and the substrate.

Rotogravure Applications

Gravure printing is used in a wide range of applications, especially in the production of flexible packaging, labels, postage stamps, banknotes and board liners. Due to its high quality and capacity rotogravure is also used in the printing of cardboard liners for food and pharmaceutical products, as it offers excellent resistance to moisture and abrasion, protecting the inks with appropriate coatings.

5 Advantages of Gravure Printing

The rotogravure printing system offers several advantages, among which are the following:

- High print quality: The printing cylinders used in rotogravure have a long service life, which reduces production costs in the long run.

- High printing quality: The printing cylinders used in gravure printing have a long service life, which reduces production costs in the long term.

- High print quality: Gravure can be used on a wide variety of substrates, including paper, cardboard, plastic and metals, making it suitable for a wide range of applications.

- High print quality: The ink used in gravure printing offers excellent resistance to moisture and abrasion, making it ideal for printing products that require durability and resistance in harsh environments. The resistance can be reinforced with varnishes.

- High print quality: Rotogravure allows the incorporation of security features such as watermarks, microtext and holograms, making it a popular choice for printing products that require authenticity and security.

Gravure Cylinder Maintenance

To ensure optimum performance and long life of the rotogravure cylinder, it is essential to carry out proper maintenance. At Ibeslab we specialise in the supply of products for daily and periodic cylinder cleaning. Water and solvent based cleaners for the dilution and removal of fresh ink used in the printing process.

Our products are ideal for manual cleaning or cleaning via the printer’s circuits.

In addition, we offer concentrated water-soluble formulations to adjust the mix for in-plant use, minimising transport and stock costs.

For cylinder deep cleaning, we have vigorous products capable of removing ink residues accumulated in the cylinder cells and compatible with solvent or water-based inks, adhesives and coatings based on polyurethane and other resins.

Special brushes and sponges to assist in the application of the products are also available.

Doctor Blade for Flexography

Graphic Arts Ink Cleaners

Band cleaner

Rotogravure Consumables

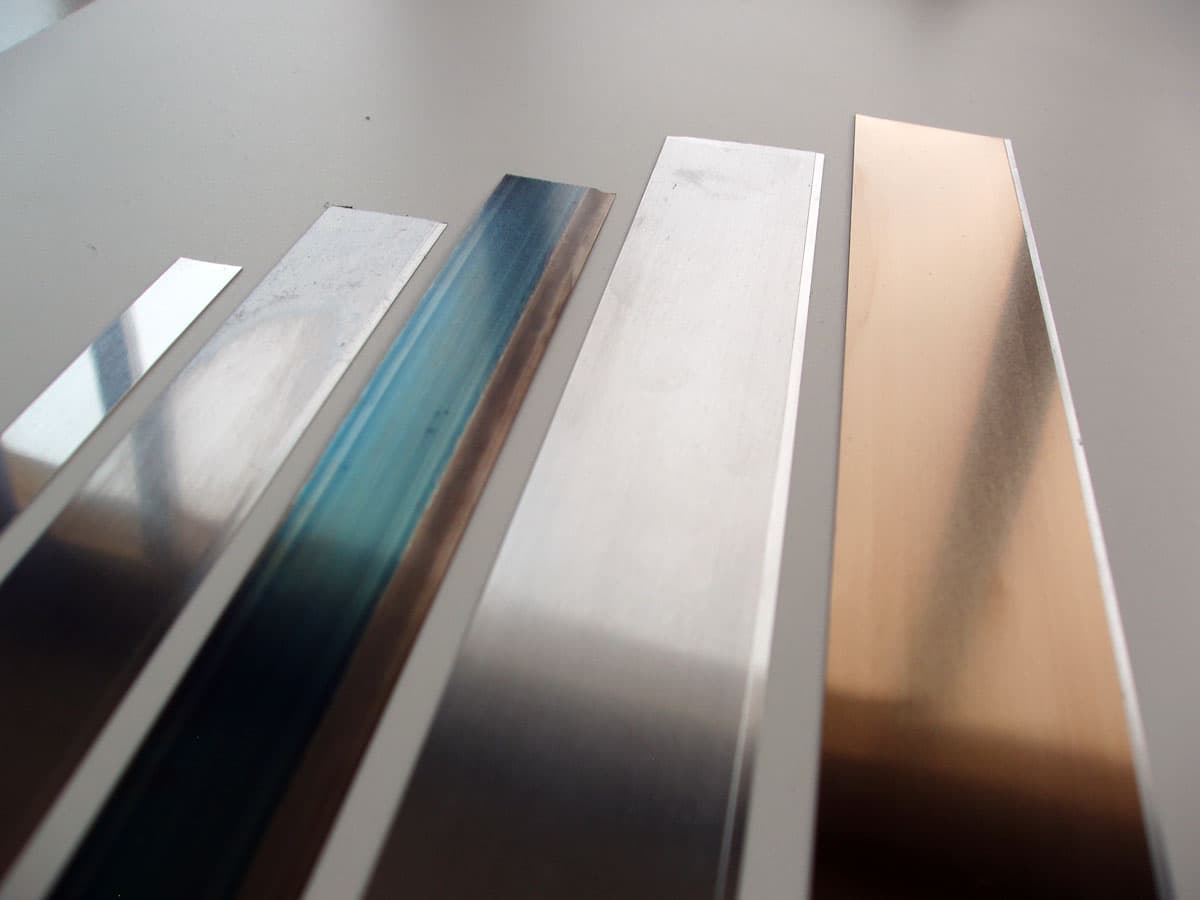

We supply Swiss steel doctor blades for rotogravure printers. We have a wide range of steel types available, with different hardnesses and geometries depending on the requirements of the machine and the application:

- Carbon steel.

- Chemically coated steel

- Ceramic coated steel

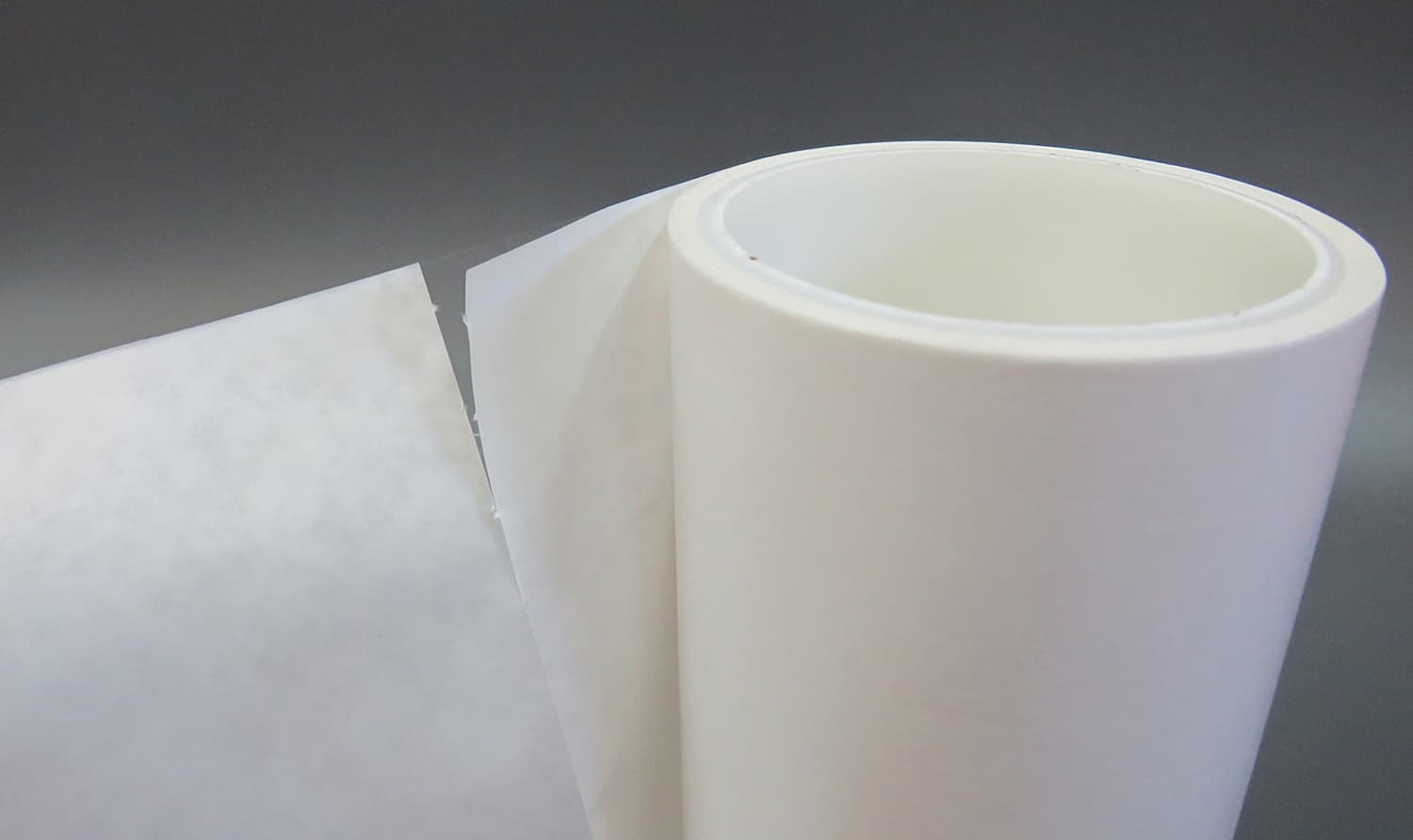

We supply special solvent and water based inks for plastic substrates and certain technical applications where the requirements differ from conventional paper or flexible packaging performance.

For flexible packaging manufacturers who produce shrink sleeves we produce special adhesives for the bonding of the film to the different plastics used in this packaging sector such as PET, PVC, PLA, OPS or PP. Our formulations incorporate UV marker additive that allows the control of the solvent dosage and the formation of the seam.

Frequently Asked Questions

Other printing techniques

Flexography

We manufacture and distribute all types of consumables used in the flexo process in the flexible packaging, labels, corrugated cardboard and paper sectors.

Screen Printing

We supply all kinds of inks and consumables for graphic printing, industrial and textile marking. Offer of printing and auxiliary machinery for serigraphic screens.