High Precision and Durability for Graphic Arts

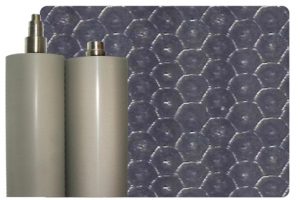

Rubber rollers for flexography

Rubber rollers are a fundamental component in a flexographic printer. In the printing and substrate flow group, they require unique quality and strength.

At Ibeslab, we provide new and re-gummed cylinders to ensure performance, durability, and quality.

Why choose our rubber cylinders?

Maximum printing precision

The formulation of the rubber and the surface finish allow for a suitable surface tension for ink transfer.

Extreme durability

The density of the rubber and the vulcanization process allow for wear resistance when in contact with inks or the substrate.

Reduction of operational costs

By requiring fewer changes due to wear, the lifespan of the cylinders is extended, reducing renewal costs and machine downtime.

Expert Support

Our team of sales engineers will assist and advise you in selecting the type of rubber and hardness based on the application.

Features of our rubber cylinders

A wide variety of rubber compounds

We use different compounds such as EPDM, NBR, Silicone, etc., depending on the machine use and mechanical requirements.

Compatibility with multiple printing technologies

The cylinders we produce are used in flexo, offset, letterpress, digital printing, and handling machines.

Customized size and hardness range

We manufacture cylinders up to 2,700 mm in length, with hardnesses from 25 to 80 Shores A, in various colors and diameters.

Coating optimized for all types of inks

We select the type of rubber based on the ink resin (water, solvent, or UV) to optimize resistance. Similarly, a surface finish is applied depending on the use of the cylinder.

Applications and industries that use our cylinders

- Flexographic and rotogravure printing companies

- Textile and paper industry

- Paper processing industry, for laminating and plasticizing

- Commercial printing, offset and digital

Frequently asked questions

The type of rubber used for the cylinder will depend on the type of inks used in the flexographic printer and the cylinder’s function in the machine.

The density of the rubber on the cylinder will depend on the type of substrate and the quality of the print. It is most common to work between 50 and 80 Shore A.

It’s hard to regenerate, unless it’s something very superficial. The usual practice is to remove all the rubber and re-coat with the original diameter and chosen density.

Contact us to determine the measures, type of application, and specific requirements. Our staff will help you through the process.

Request your quote today

Boost the quality and efficiency of your production with Ibeslab rubber cylinders. You just need some basic information, and our specialists will send you a detailed, no-obligation proposal.