Types, uses, and solutions for professionals

Cylinders for flexography

The flexographic cylinders from IBESLAB are designed to maximize printing performance, ensuring high precision and durability..

Discover all our options and request personalized advice.

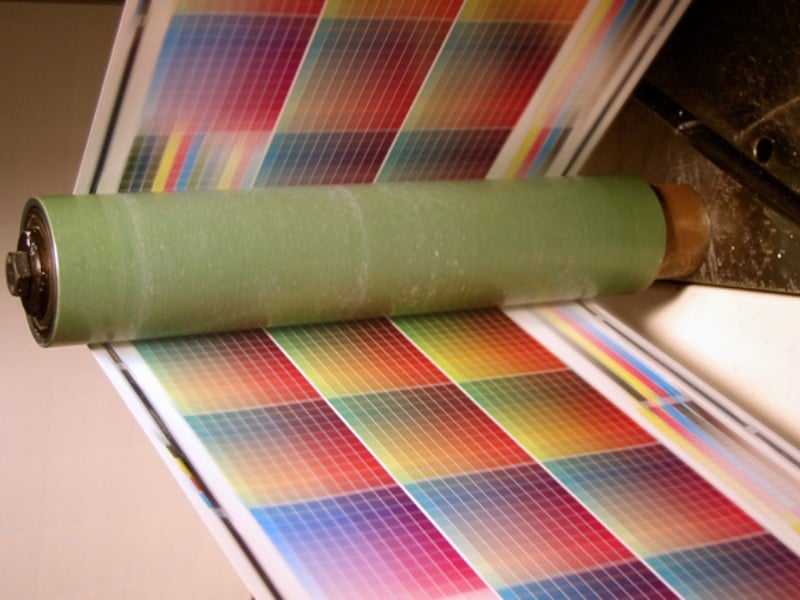

A key component in professional printing

Flexographic printing cylinders perform critical functions in ink transfer, web support, and die-cutting precision. Choosing the right cylinder with the correct quality and precision directly impacts the final quality and efficiency of the process.

Types of cylinders for flexography

- Value: Custom-made manufacturing on demand

- Advantages: Dimensional stability, lightweight designs for high-speed printers.

- Applications: Continuous labels, flexible packaging, corrugated cardboard.

- Finishes: Surface tension control

- Components: technical alloys and special rubbers.

- Typical uses: Laminating, varnishing, special effects.

- Design: Ergonomic for easy handling

- Compatibility: Various types of ink and industrial systems.

- Benefits: Ease of use for the operator.

- Innovation: Special treatments and state-of-the-art magnets.

- Advantages: Accuracy, reduction of downtime, quick changes.

- Uses: High-speed rotary punching and labeling.

Technical advantages of our cylinders

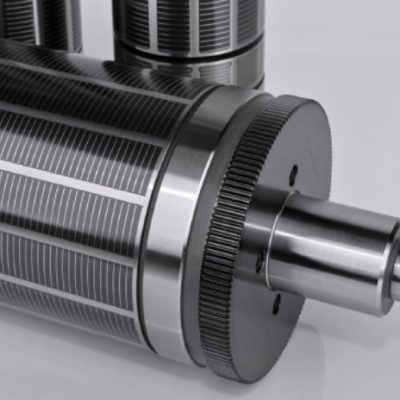

Our cylinders are made of high-strength stainless steel and special alloys that allow for superior performance even in intensive production conditions.

These materials not only offer high resistance to wear and corrosion, but also ensure a longer component lifespan.

The heat–treated axles and running tracks achieve a higher hardness of up to 62 HRC, thus guaranteeing their prolonged performance under high loads and speeds.

In terms of precision, the cylinders are machined with CNC technology that allows for extremely tight tolerances, of up to -/+ 0.003 mm.

This millimeter-level manufacturing capability contributes to the stability of the registration and prevents deviations during die-cutting or printing, which are crucial factors in achieving consistent results.

Additionally, technical customization is one of our major differentiators: we can adapt the weight of the cylinder according to the equipment, offer different types of coatings according to the type of ink or substrate, and integrate specific components such as positioning pins or structural reinforcements.

These adaptations allow each cylinder to fit perfectly into the customer’s workflow.

✅ High durability and resistance to demanding environments

✅ Maximum compatibility with flexo, offset, and varnishing equipment

✅ Accuracy that minimizes errors, waste, and rework

Key benefits for your company

Optimize your time: quick changes and less need for unscheduled maintenance allow you to keep production active with minimal interruptions, significantly speeding up processes and reducing downtime.

Save on operating costs: thanks to the robustness of the materials and the optimized design of the cylinders, their lifespan is extended, reducing the frequency of replacements and the cost of repairs, which improves the profitability of operations in the long term.

Consistent accuracy: each cylinder guarantees dimensional stability and precise ink or varnish transfer, even in long runs, allowing for homogeneous results in different printing cycles without the need for frequent adjustments.

Ibeslab Solutions

Personalized Advice

Our technical team will help you choose the ideal solution for your system and needs. Contact us to:

- Selection of cylinders by material type and system.

- Customized solutions by industry.

- Immediate and non-binding quote.

frequently asked questions

The lightweight or magnetic printing cylinders are ideal due to their dimensional stability and ease of assembly.

Yes, we adapt each cylinder to the technical specifications of your system: weight, coatings, and couplings.

Only periodic cleaning. Its robust design and durable materials minimize maintenance.

It depends on the type of cylinder and customization, but generally we deliver in 5 to 10 business days.