Precision and Durability for the Best Print Quality

Printing Cylinders

Our printing cylinders combine precision engineering, high-quality materials and strict manufacturing control to deliver optimal performance with every print run.

By choosing us, you get maximum durability and dimensional stability, reducing both maintenance costs and downtime.

Features of our printing cylinders

Printing cylinders with shafts

Cliché cylinders made of aluminium with optional anodised treatment. With cutting and positioning lines to facilitate photopolymer assembly.

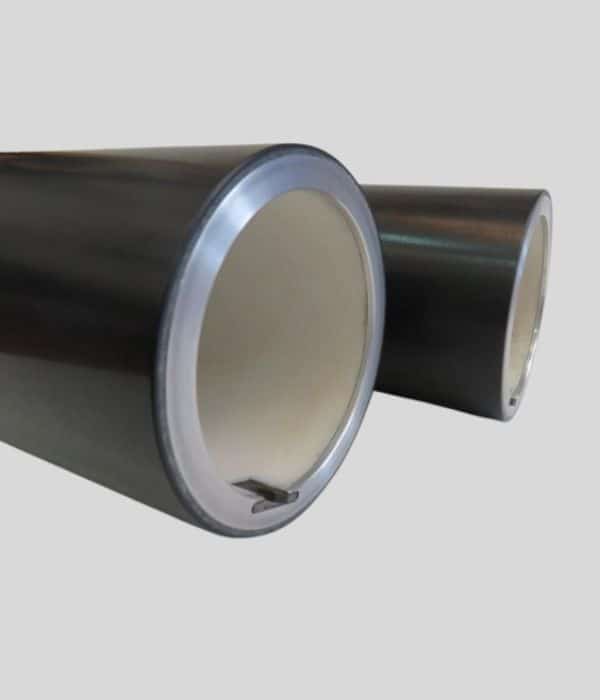

Lightweight Printing Cylinders

Designed with weight-reducing alloys, making them easier to handle and increasing efficiency. Their lower inertia allows for higher printing speeds and less wear and tear, ideal for frequent changes.

Printed shirts

Hollow cylinders made of composite or fibreglass. They facilitate handling in large-bandwidth printers. With reinforced edges and registration pin.

Auxiliary cylinders

Hardened support cylinders. Cylinders for slitting, cutting or handling on reel stands. High-precision metal cylinders for other special applications.

Technical Details and Specifications

We develop our printing cylinders in a variety of materials ranging from high-strength steel to aluminium alloys and special composites. We also offer ceramic coatings or high-hardness surface treatments to protect the cylinder from corrosion, friction wear or abrasion, extending its service life and maintaining optimal ink transfer.

We can manufacture cylinders to suit a wide range of diameters and lengths, depending on the requirements of each machine or printing process. Our precision machining processes guarantee minimum tolerances in concentricity, balance and roughness, resulting in consistent and repeatable printing, even on long runs.

We have advanced CNC turning and milling systems, high-precision grinding and polishing processes, as well as laser engraving equipment for extremely detailed designs. In addition, we perform quality controls at multiple stages of production, validating dimensions, coating hardness, alignment and dynamic balance, ensuring that each cylinder meets the highest international standards.

Nuestros cilindros se caracterizan por su durabilidad, bajo mantenimiento y menor tiempo de inactividad, reduciendo así el coste total de propiedad. La precisión dimensional y la uniformidad en la superficie proporcionan resultados consistentes en la transferencia de tinta, mejorando la calidad de la imagen impresa. De este modo, se optimiza la eficiencia productiva y se minimizan las mermas, favoreciendo una respuesta rápida a las exigencias del mercado.

Applications and Industrial Sectors

Label and flexible packaging printing

They offer consistent precision for flexographic printing on self-adhesive materials, plastic film and paper. Guaranteed uniform results.

Corrugated cardboard, paper, plastic film

Its durability and easy adjustment allow for extended runs with different materials, ensuring consistent registration and minimising production line stoppages.

Supplies for the food, pharmaceutical and cosmetics industries

With special coatings and strict tolerances, we meet high standards of quality and hygiene, offering impeccable and safe finishes for sensitive markets.

The Future of Your Printing Starts Here

Rely on our printing cylinders to optimise your production processes and achieve flawless results in every project. Our extensive experience, cutting-edge technology and commitment to customer satisfaction guarantee tailor-made solutions.

¿Listo para dar el siguiente paso? Ponte en contacto con nosotros hoy mismo para recibir asesoría personalizada o solicitar una cotización. Invertir en cilindros de impresión de alta calidad es la mejor manera de asegurar la productividad, la durabilidad y la excelencia en todas tus impresiones.